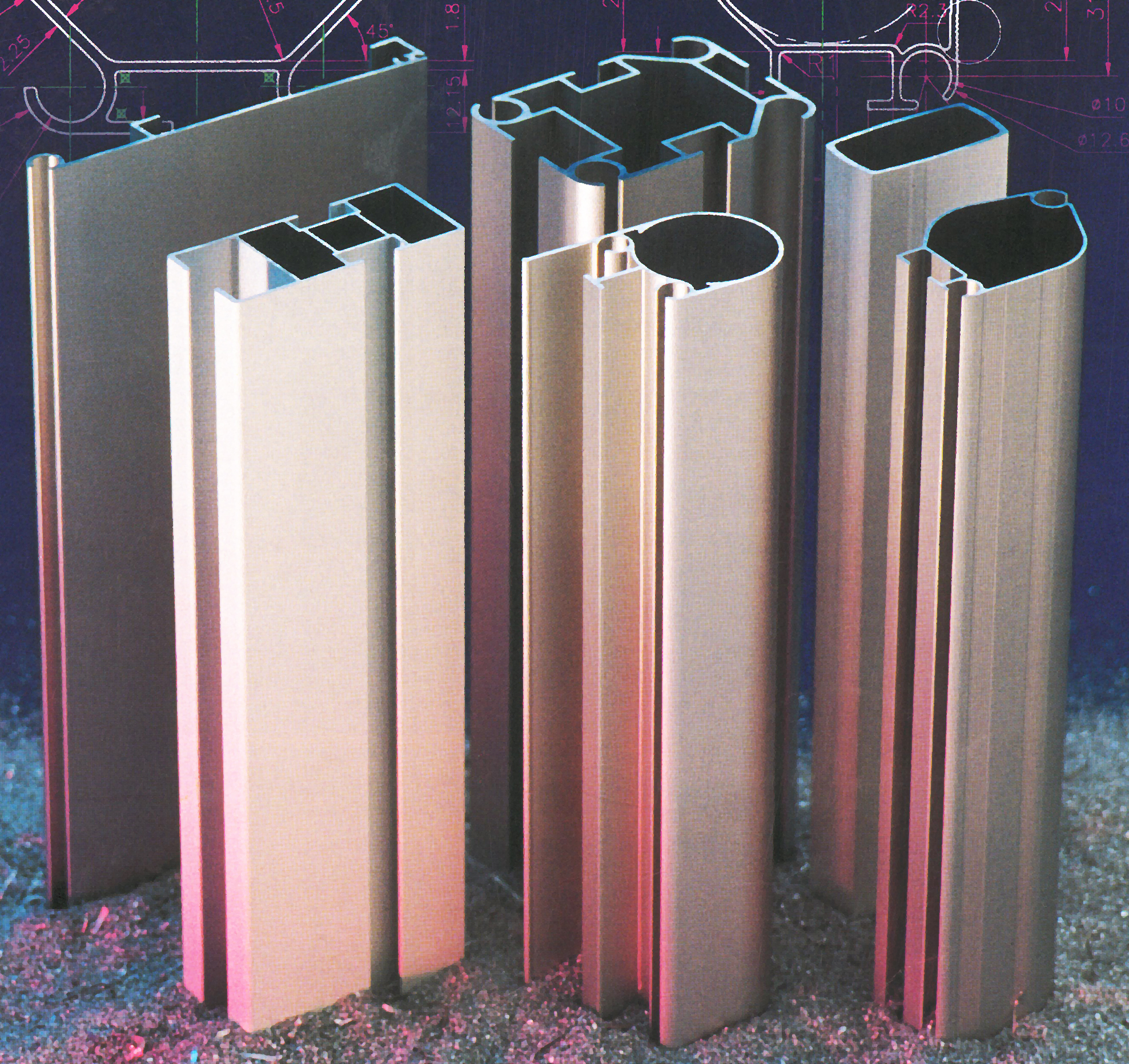

Our extrusion press in Pierrefitte Nestalas (France) is suitable for all types of extruded projects for very long lengths.

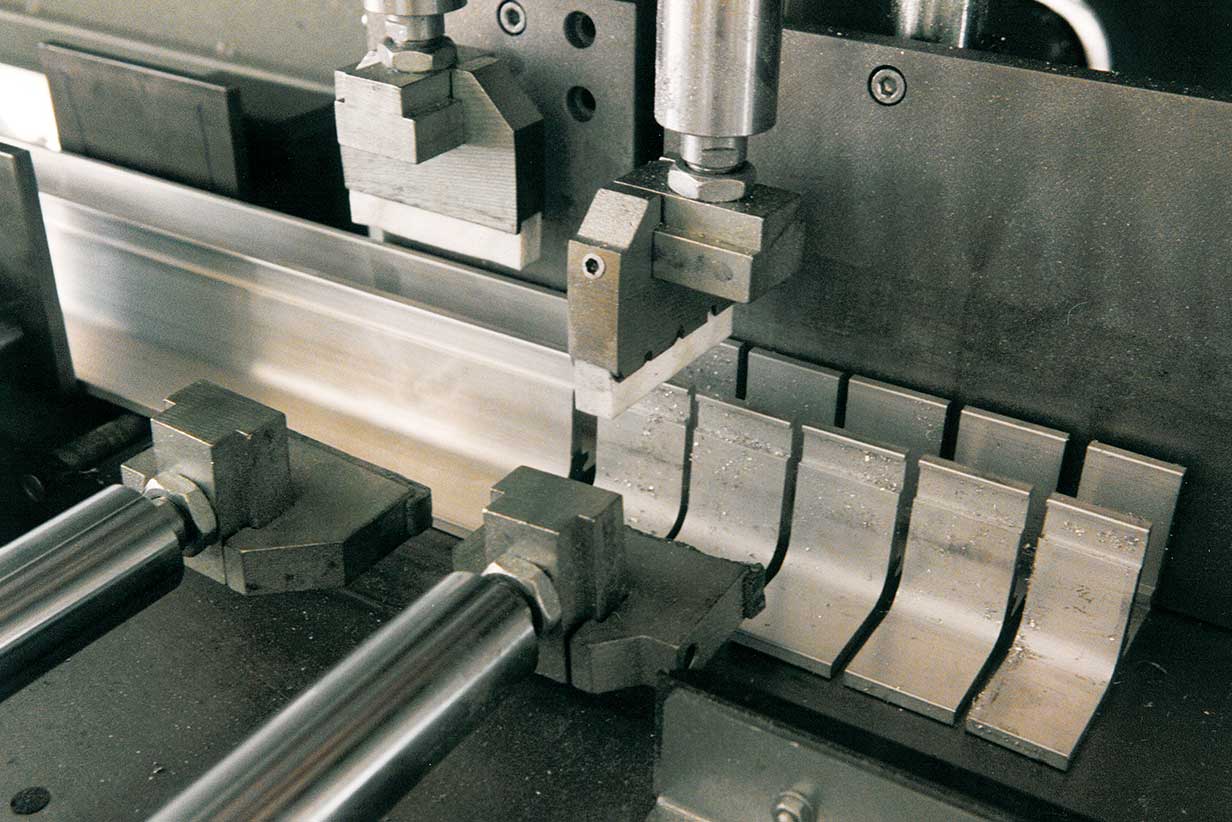

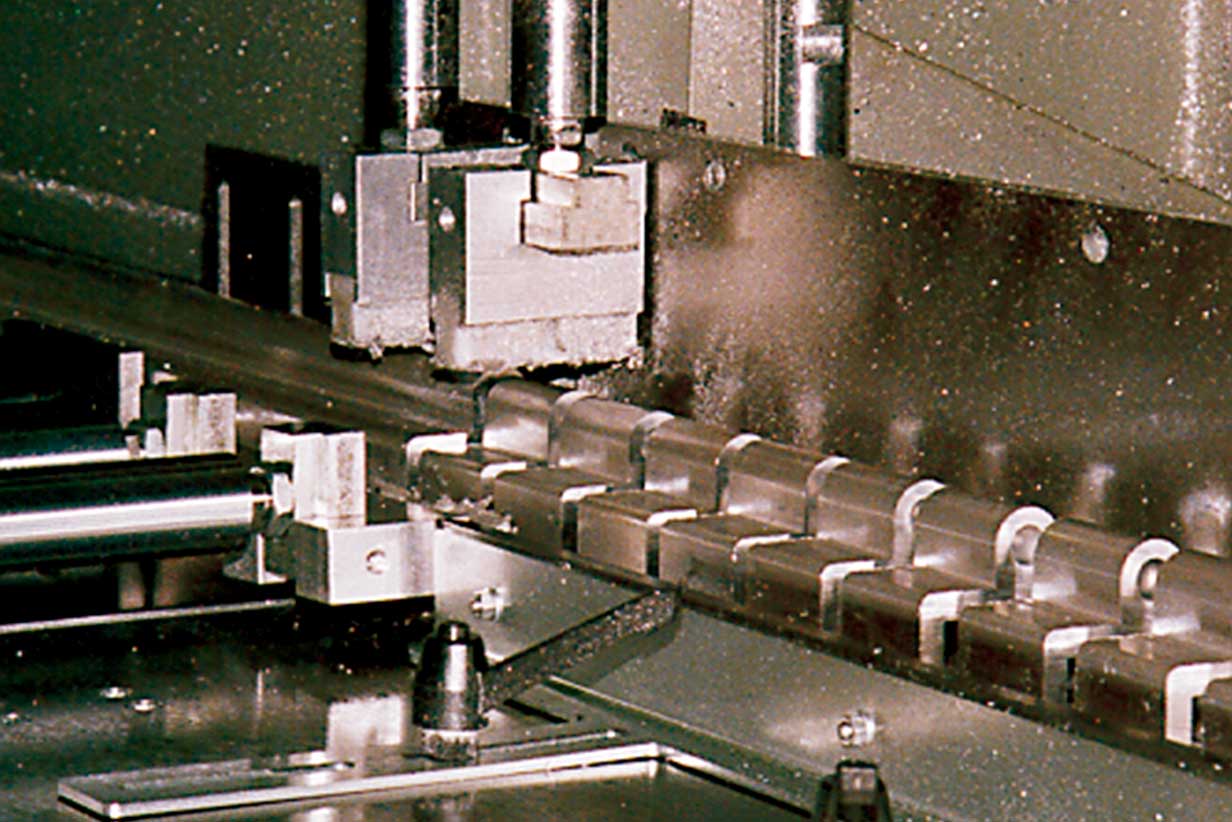

What is extrusion? This is a thermo-mechanical manufacturing process. Under stress, a compressed material passes through a die shaped in the desired profile. A long product can therefore consistently be obtained and cut to the size desired by the customer. The result obtained on the cooling and stretching table can be tubular or solid.

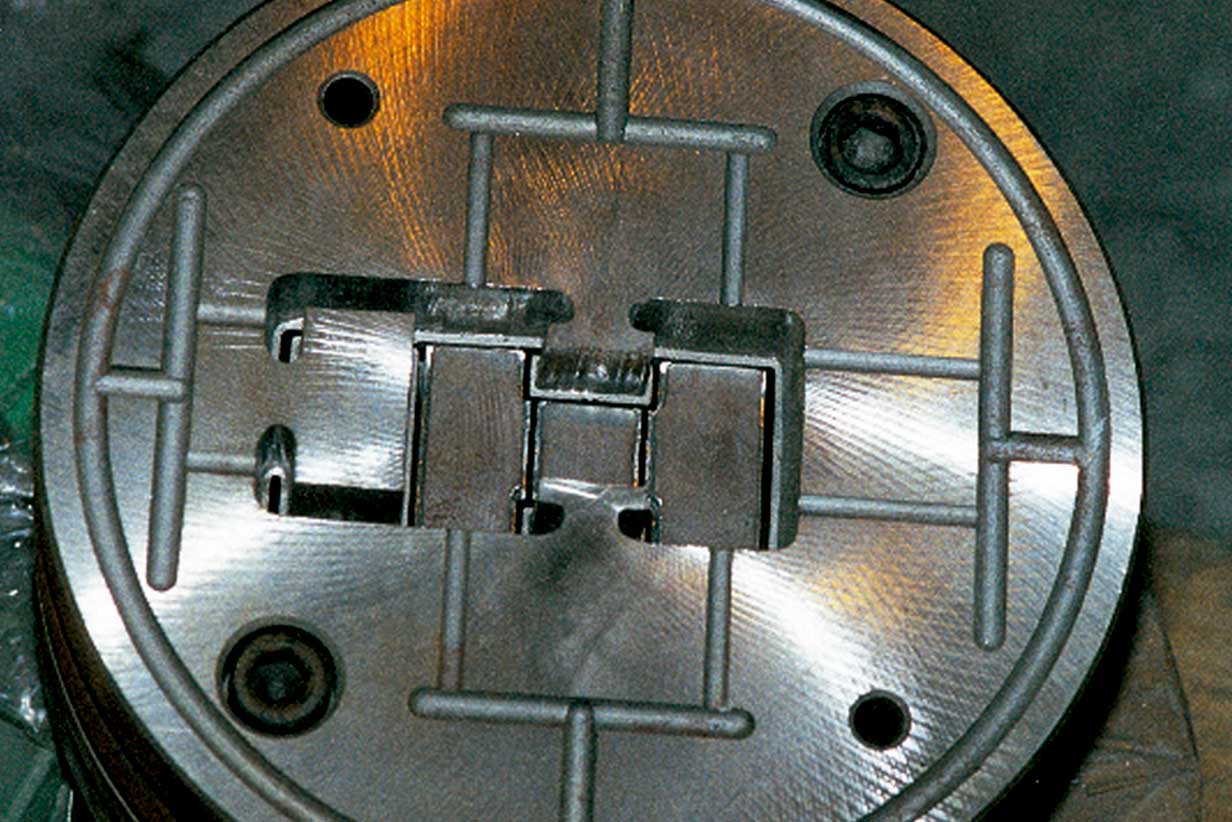

A billet, a compressed and full cylinder, heated to at least 500° is placed in a hollow container and pushed so that it becomes what is called a “profile”.

This process, which is essential know-how in the manufacture of our products, is shown in the video opposite.